wire wound resistor is better for accuracy!

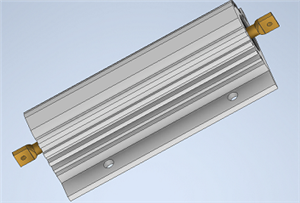

Wire wound were the only garantee for precision resistances. Wirewound resistors have some important characteristics, they have very tight resistances tolerances, 0.005% is commonly achieved. More important, they are maintaining their precision over time because they are made with stable material, TCR is low than 10ppm.

There are two common film types, thick film and metal or think film. Thick film resistors are made by silk-screening conductive paint onto an insulating substrate. The paint is "fired" to make the assembly permanent.Thick film resistors have many carbon resistor characteristics, on the good side, they can be made small and are low cost in high quantities. However, they cannot have tight resistance tolerance and have large TCR and they are unstable.

Metal film resistors are a better technology, they are made by an evaporation process with base maetal is vaporized in a vacuum and deposited on an insulating substrate. Compare to precision wirewound, they are not accurate, have higher TCR and are not as stable .They can be small for "chip" applications are low cost in high quantities, and are excellent in high frequncy and fast rise time applications

But if ACCURACY is critical - Use wirewound resistors!