-

Thunder Precision Resistor Co., Ltd. applied RoHS and Reach Test to guarantee all materials used in the products as well as the packing materials meet the Restriction of Hazardous Substances and REACH/SVHC requests. Thunder Precision Resistor Co., Ltd. requested all the material suppliers to provide RoHS and REACH/SVHC test reports annually and applied the RoHS and REACH/SVHC tests our selves occasionally to make sure all materials are under control even the packing materials. Thunder Precision Resistor Co., Ltd. makes high precision resistors and special resistors, such as high power precision wire wound resistors up to 150W with temperature coefficient low than 15ppm, high resistance resistors up to 10G Ohm with temperature coefficient of resistance lower than 25ppm/℃, ultra-precision resistors with tolerance up to 0.005% and temperature coefficient lowen than 1ppm/℃, high resistance wire wound resistors with resistance up to 100k Ohm, etc.

-

晶圆电阻(melf resistors) 焊接效果目视检查项目与合格判据表 Visual inspection items and qualification criteria of welding effects for melf resistors extracted from IPC-A-610G by Thunder Precision resistor Co., Ltd.

-

分级说明:本文件规定的要求反映了如下三个产品级别:晶圆电阻使用厂家可以根据自己产品的定位选择合格判据的级别 1级:是使用在普通类电子产品中的仪器仪表生产过程中的检验要求; 2级:是使用在有可靠性要求的仪器仪表产品、设备的生产制造过程中的检验要求; 3级:是使用在有较高可靠性要求的仪器仪表产品、设备的生产制造过程中的检验要求

-

MELF type ceramic resistors HPCM series are high pulse load resistors that are the good choice of ignition resistors of motorcycle and automobile starting system.

-

SGShad made the wetting balance tests to prove the perfect solder-ability of the precision melf resistors made by thunder precision resistors. The result of the test declared the high quality of the precision melf resistors made by thunder precision resistors.

-

Thunder Precision Resistor Co., Ltd. had made the wetting balance tests to prove the perfect solder-ability of the precision melf resistors made by thunder precision resistors. The test was made by SGS and the result of the test declared the high quality of the precision melf resistors made by thunder precision resistors.

-

Fusible wire wound resistors FEATURES · Advanced alloy wire technology · Fusible less than 60 seconds when against 25 times power abnormal applied or according to customer’s request · Reliable in pulse / transient / abnormal surge applications · Non-inductance winding available upon request · Flame retardant coating

-

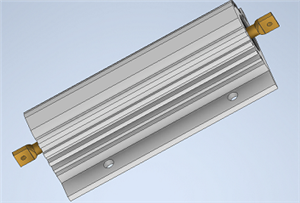

FEATURES · Advanced Isabellenhütte alloy technology · Very low TCR: lower than ±10ppm/℃. · Tolerance up to ±0.1% · Excellent overall stability: Class 1 · Very low noise and voltage coefficient · Non-inductance winding available under request · Perfect pulse loading capability: over 25 times rated power loading · Extremely high dielectric strength: stand over 3000VDC insulation voltage Thunder Precision Resistor Co., Ltd has been making precision wire wound resistors with tiny size housed in aluminium shell.

-

Thunder Precision Resistor Co., Ltd. disclosed the process and preparation methods of making a new kind of UHF RF resistors: (1) Take a certain mass of nano silicon carbide with a particle size of 20nm ~ 50nm and disperse it in 95% ethanol with a mass multiple of 5 ~ 8 times, and then add nano alumina with a particle size of 20nm ~ 50nm with a mass of 2 ~ 3 times of nano silicon carbide to fully disperse it; (2) Add silane coupling agent dl602 with 2% ~ 3% mass of nano silicon carbide, fully stir until the system thickens, and then add organic Polyborosilazane iota-9120 with 0.3 ~ 0.5 times mass of nano silicon carbide to fully disperse; (3) in air atmosphere, the mixture of step 2 (step 2) was desiccant and cured by spray drying method, and the modified filler was prepared.

-

RN series high stable metal film resistors with stability established Thunder Precision Resistor Co., Ltd. makes RN series resistors that meet requirements of MIL-R-55182 with established reliability. The hard Bakelite mold construction provides superior moisture protection RN series high stability resistors are made of 96% alumina ceramic cores sputtering with high grade professional metal film trimmed with the professional laser machines to achieve uniform helix grooves without hurt the ceramic cores. The production procedure is introduced from Europe in 1989. All materials of to make RN series high stability resistors have been keep the same as they are introduced to guaranty the high quality and high stability as well.