-

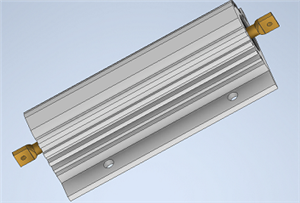

Fusible wire wound resistors FEATURES · Advanced alloy wire technology · Fusible less than 60 seconds when against 25 times power abnormal applied or according to customer’s request · Reliable in pulse / transient / abnormal surge applications · Non-inductance winding available upon request · Flame retardant coating

-

FEATURES · Advanced Isabellenhütte alloy technology · Very low TCR: lower than ±10ppm/℃. · Tolerance up to ±0.1% · Excellent overall stability: Class 1 · Very low noise and voltage coefficient · Non-inductance winding available under request · Perfect pulse loading capability: over 25 times rated power loading · Extremely high dielectric strength: stand over 3000VDC insulation voltage Thunder Precision Resistor Co., Ltd has been making precision wire wound resistors with tiny size housed in aluminium shell.

-

Thunder Precision Resistor Co., Ltd. disclosed the process and preparation methods of making a new kind of UHF RF resistors: (1) Take a certain mass of nano silicon carbide with a particle size of 20nm ~ 50nm and disperse it in 95% ethanol with a mass multiple of 5 ~ 8 times, and then add nano alumina with a particle size of 20nm ~ 50nm with a mass of 2 ~ 3 times of nano silicon carbide to fully disperse it; (2) Add silane coupling agent dl602 with 2% ~ 3% mass of nano silicon carbide, fully stir until the system thickens, and then add organic Polyborosilazane iota-9120 with 0.3 ~ 0.5 times mass of nano silicon carbide to fully disperse; (3) in air atmosphere, the mixture of step 2 (step 2) was desiccant and cured by spray drying method, and the modified filler was prepared.

-

0304-2022

New invention patent approved

Thunder Precision Resistor Co., Ltd. had disclosed an invention of an ultra-high frequency RF resistor and a production method thereof. The new invention patent had be approved and issued. The diamond substrate is used as the substrate material, the composite heat dissipation substrate is used to improve the heat dissipation efficiency, and the special packaging material is used to further improve the heat dissipation performance of the RF resistor. The production method uses liquid nitrogen cooling to control the temperature rise of laser resistance adjustment, laser seamless welding and laser cutting, so as to prevent the resistance value variation of the resistance layer of the RF resistor during the production process.

-

RN series high stable metal film resistors with stability established Thunder Precision Resistor Co., Ltd. makes RN series resistors that meet requirements of MIL-R-55182 with established reliability. The hard Bakelite mold construction provides superior moisture protection RN series high stability resistors are made of 96% alumina ceramic cores sputtering with high grade professional metal film trimmed with the professional laser machines to achieve uniform helix grooves without hurt the ceramic cores. The production procedure is introduced from Europe in 1989. All materials of to make RN series high stability resistors have been keep the same as they are introduced to guaranty the high quality and high stability as well.

-

Thunder-precision-resistor-get-another-specialized-and-special-new-enterprise-certificate issued by Province Government on 2022.02.24. Thunder Precision Resistors is a professional manufacturer of high precision resistors for more than 29 years. Thunder Precision Resistors has issued two new invention patents about new procedure of making special RF resistors and five utility model patents related to mechanics and technology.

-

1002-2022

Founding of Thunder Precision Resistors

Thunder Precision Resistors has more than 29 years of experience in developing, designing and manufacturing qualified high precision resistors. All productions are strictly controlled and follows an extensive set of instructions established in production procedure for reproducibility which was introduced from Europe. The quality of the products is always the first priority of Thunder Precision Resistors that is also our company quality policy. BSI issued ISO9000 Quality Management Certificate to Thunder Precision Resistors in 1998 and upgraded it in June 2016 to ISO9001:2015.

-

MELF (metal electrode lead-free surface) resistors can be soldered by reflow and wave soldering. The welding effect and strength shall meet the corresponding requirements of this standard extracted from ipc-a-610f and the experience summary of actual test results

-

1911-2021

new ISO14001 CERTIFICATE

Thunder precision resistor Co., Ltd. is a 29 years experienced manufacturer of high precision resistors and special resistors such as high voltage resistors, high working frequency non-inductance resistors, high resistance wire wound resistors with tight tolerance and high stability, etc. ISO14001:2015 certificte issued by BSI shows Thunder precision resistor Co., Ltd makes all products compliant to RoHS directive 2011/65/EUand Compliant to REACH (EC No. 1907/2006)) (last updated: 27/06/2018).